Ball Milling Method – Principle, Working, Diagram & Applications

Quick Exam Notes

- Type: Top-Down approach for nanoparticle synthesis

- Equipment: Rotating drum with grinding balls

- Principle: Impact and attrition reduce particle size

- Duration: 8–24 hours depending on desired particle size

- Applications: Nanopowder synthesis, alloys, material science

Ball milling, also called mechanical crushing is a popular method to synthesize nanopowders of various solid materials. This comes under Top-Down approach of nanomaterial synthesis. The following is the process flow to synthesize nanomaterial by ball milling method.

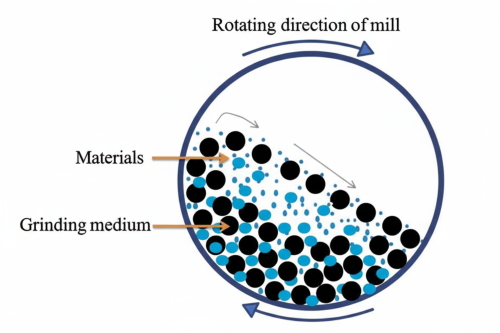

Figure 1: Ball Milling Method Diagram for Nanoparticle Synthesis

Working of Ball Milling Method

- The method uses a rotating cylindrical drum into which raw material (large particles) is loaded.

- Grinding media such as iron balls or zirconia beads of different diameters are added to the drum.

- A mixing medium (ethyl alcohol, acetone, or distilled water) is often used to improve milling efficiency.

- The drum is rotated at high RPM using a motor, causing collisions between the balls and powder particles.

- The particles are broken down by impact (collision) and attrition (friction), reducing them to nanosize.

- Typical milling time is 8–24 hours to obtain uniform nanopowder.

- By adjusting RPM, duration, ball size, and medium, the final particle size and distribution can be controlled.

Applications of Ball Milling Method

- Used for nanoparticle synthesis of metals, oxides, carbides, and alloys.

- Preparation of nanocrystalline powders for research and industry.

- Production of magnetic and semiconductor nanomaterials.

- Used in pharmaceuticals to prepare fine powders and drug carriers.

- Applied in ceramics and composites to achieve uniform microstructures.

Advantages of Ball Milling Method

- Ease of synthesis

- Low cost compared to other nanomaterial synthesis methods

- Environment-friendly and non-toxic process.

- Low temperature processing

Disadvantages of Ball Milling Method

- Time consuming

- Loss of materials

- Chances of contamination is more

- Non-uniform particle size distribution

Summary

The ball milling method is a top-down approach for nanoparticle synthesis based on the principle of impact and attrition. A rotating cylindrical drum, filled with grinding balls and raw material, is driven at high speed. Collisions between balls and the material break particles into nanoscale powders. Milling duration, ball size, and rotation speed control particle size.

FAQs on Ball Milling Method

Q1: What is the principle of Ball Milling Method?

Ans: The principle is impact and attrition. Grinding balls strike and crush the material inside a rotating drum, reducing it to nanopowder.

Q2: What are the advantages of Ball Milling Method?

Ans: It is simple, low-cost, non-toxic, and suitable for large-scale nanoparticle synthesis.

Q3: What are the limitations of Ball Milling?

Ans: It is time-consuming, may cause contamination, and produces non-uniform particle sizes.